Cutting

Subsea Cutting Solutions

DECO Subsea is a global provider of world class cutting services. Over the years, DECO Subsea has developed and built an extensive range of subsea cutting tools for various applications based on ultra-high pressure (UHP) abrasive water jet and diamond wire cutting technology. Our broad knowledge and experience also enables us to design and build custom-made cutting tools and solutions when required.

General cutting solutions

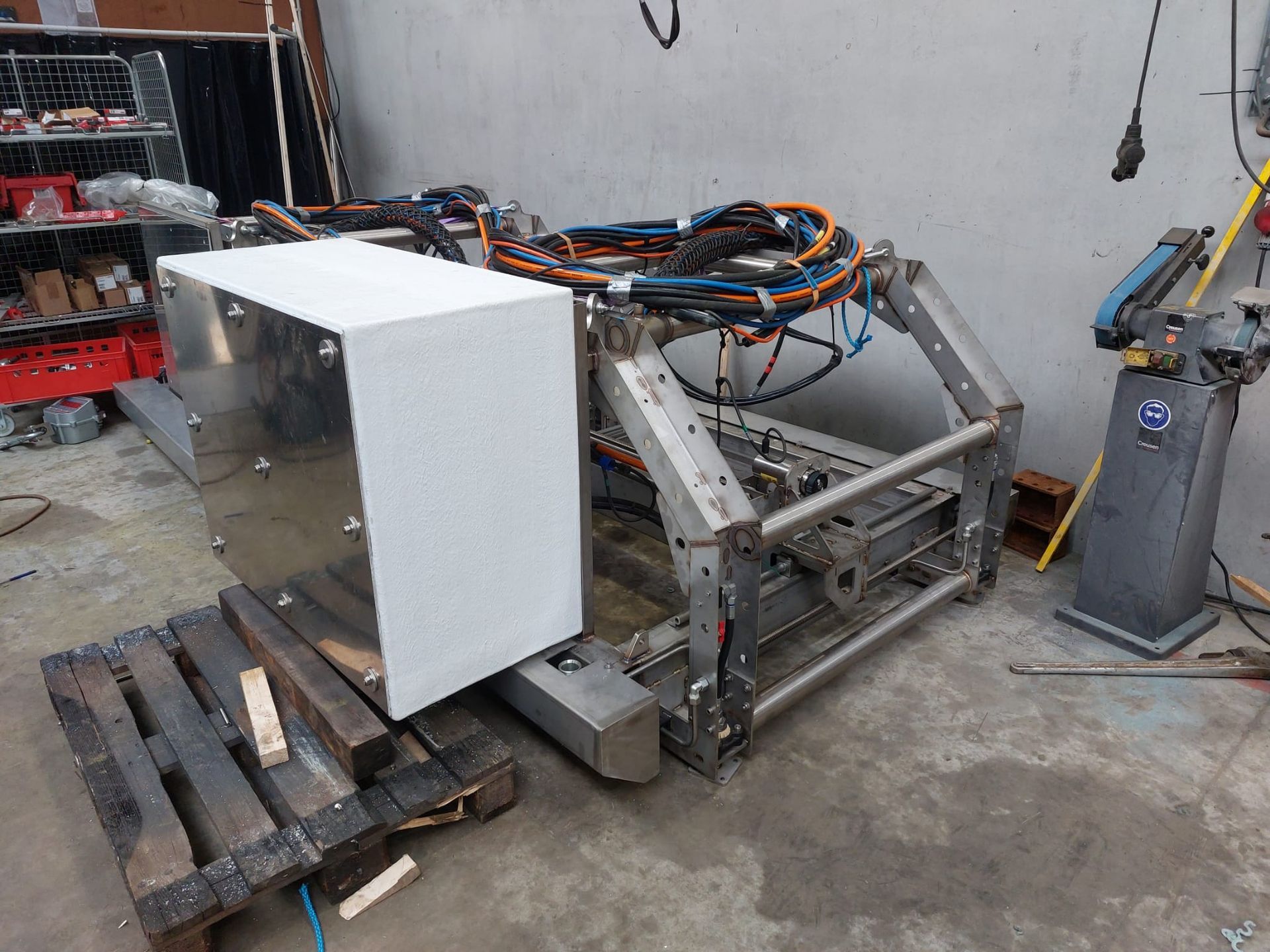

DECO Subsea designs, develops and implements cutting solutions according to your requirements. Depending on the requirements, our cutting solutions are based on UHP abrasive waterjet cutting or diamond wire cutting technology.

We build project-focused tools for external pile cutting, rack-and-pinion cutting, access to wrecks, cold cutting for welding, blind cuts in concrete - you name it, we build it.

All our cutting frames and systems are adaptable for work on quay walls, piles, topsides and other structures both above the water surface and below. Most are available with various remote control and automation options that make them suitable for topside control, shallow water diver control or ROV control.

Internal pile cutting

Subsea pile cutting operations are commonly performed during installation and/or decommissioning works for offshore oil & gas and offshore wind structures (jackets and monopiles). For a variety of reasons, internal pile cutting is usually the preferred option.

All our internal cutting tools make use of DECO Subsea's patented ultra-high pressure abrasive water jet subsea cutting technology which is the result of more than two decades

of research and development. Today, DECO Subsea sets the industrial benchmark in this technology with class leading cutting power, unparalleled cutting speed and exceptional reliability.

Our cutting power easily allows us to cut with a single pass through 230mm high tensile steel, 450mm cast iron, 1200mm reinforced concrete and 36" 4-string conductors. Our track record shows more than 1400 piles cut at waterdepths up to 130m below LAT.

Our portfolio of existing internal cutting tools allows us to cut any pile with internal diameter between 550mm and 3000mm. In view of future requirements, we have designs ready for fabrication of internal cutting tools for pile diameters up to 10m.

For maximum efficiency, all our internal cutting tools can be combined with a pile clamp arrangement which allows to cut and lift the cut pile section in a single crane operation.

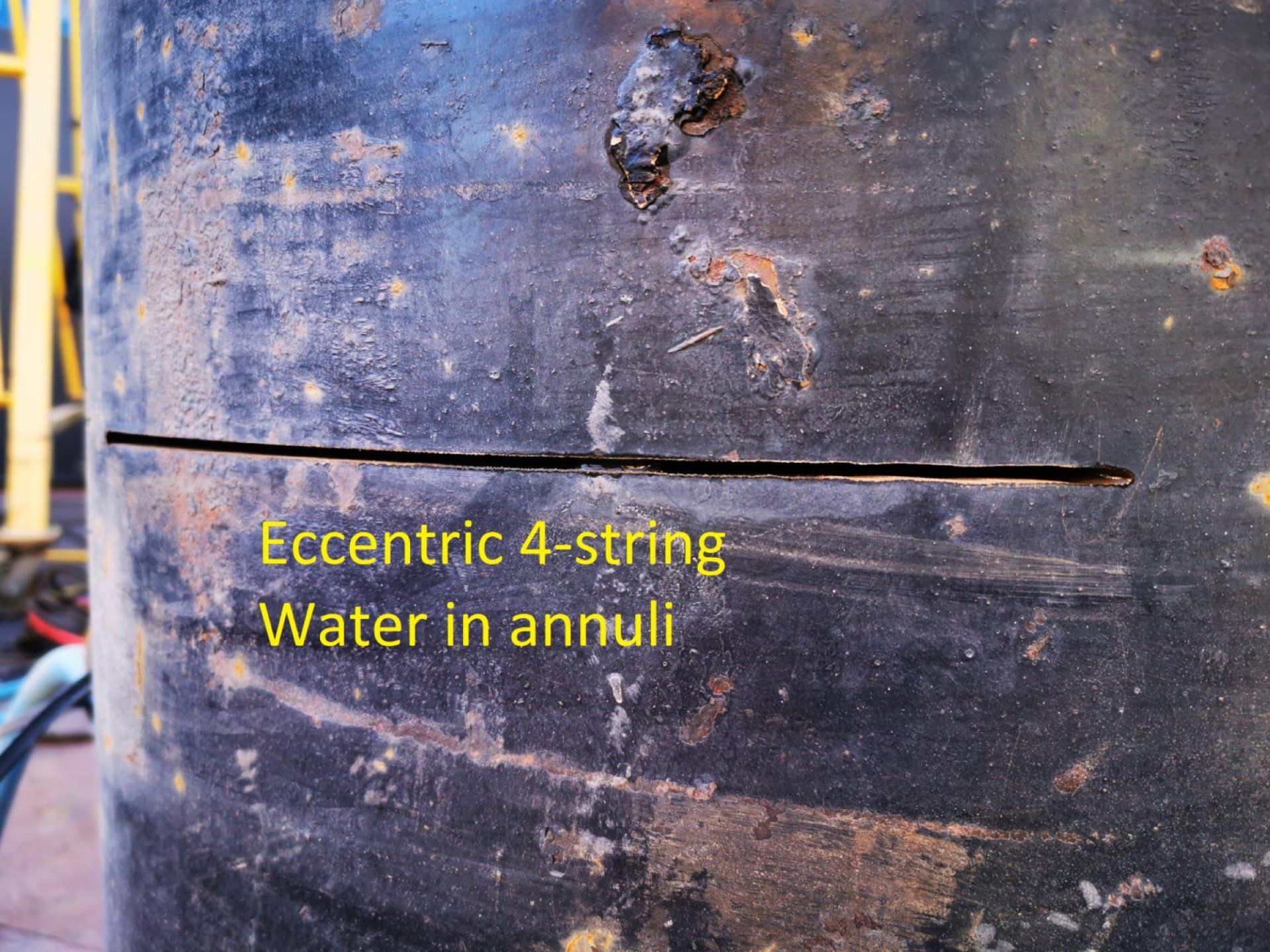

Conductor cutting

Abandonment is the final stage of every well. Conductor and casing removal is an integral and critical component of any well P&A project.

With DECO Subsea's (in-house designed) tested and proven

conductor cutting tool, multi-string conductors can be cut efficiently and safely. Our conductor cutting tool makes use of the same patented ultra-high pressure abrasive water jet subsea cutting technology as all our other tools thereby providing class leading cutting power, unparalleled cutting speed and exceptional reliability.

Our cutting power easily allows us to cut with a single pass through 230mm high tensile steel, 450mm cast iron, 1200mm reinforced concrete and 36" 4-string conductors. Our track record shows more than 1400 piles cut at waterdepths up to 130m below LAT.

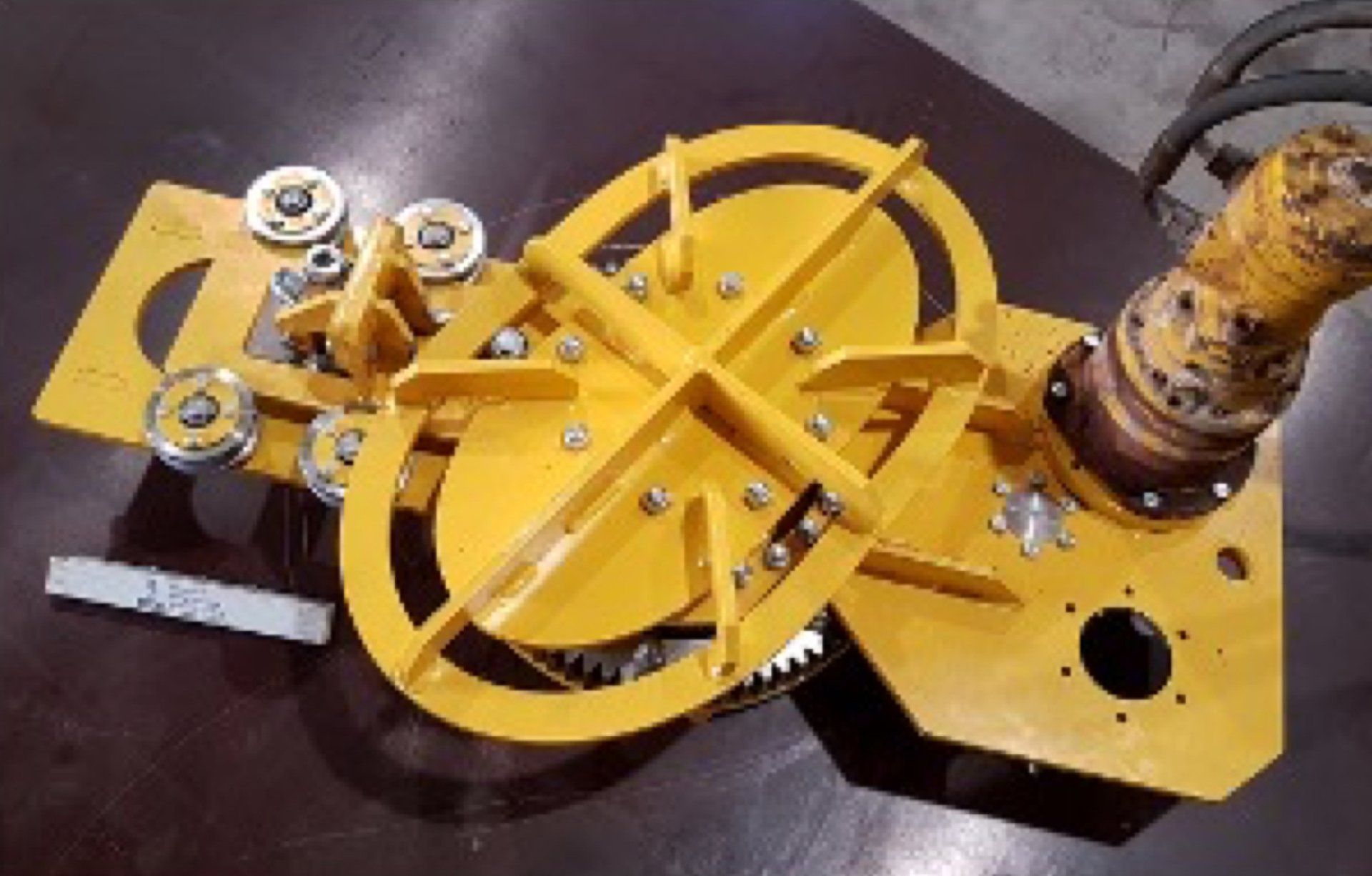

Hole cutting

DECO Subsea designs, builds and operates a wide range of hole cutting tools based on it's patented ultra-high pressure abrasive water jet subsea cutting technology. The standard range of hole cutting tools can be used to cut circular holes, elliptical holes or X-Y windows (i.e. square or rectangular holes) but in principle any shape is possible.

To date DECO Subsea has cut over 850 holes for applications ranging from water replenishment, drainage and cable entry holes to shackle and

trunnion holes. Depending on the application, these holes were cut during installation, operation or decommissioning phase of offshore windfarms, oil & gas structures and ship wreck removal.

CONTACT US

© 2021 Deco Subsea | Privacy policy